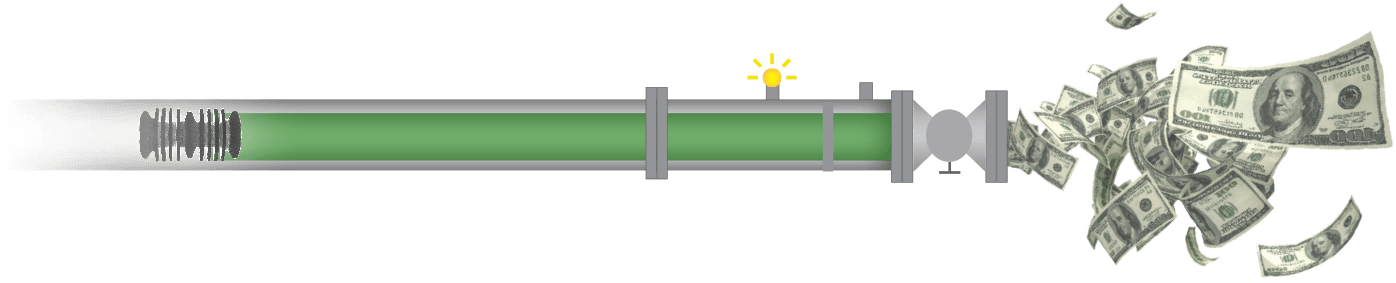

Understanding Why a Pigging System is Right for You

Raw material, manufacturing, and waste disposal costs are rising. At the same time, customers are placing smaller, more frequent orders and demanding higher product quality. Hygienic pigging systems provide significant cost savings by recovering previously lost product from pipelines and eliminating flush waste and disposal expenses. Hygienic systems help manufacturing plants become more competitive, attain sustainable manufacturing and continuous improvement goals, and become better stewards of the environment.

Average Returns

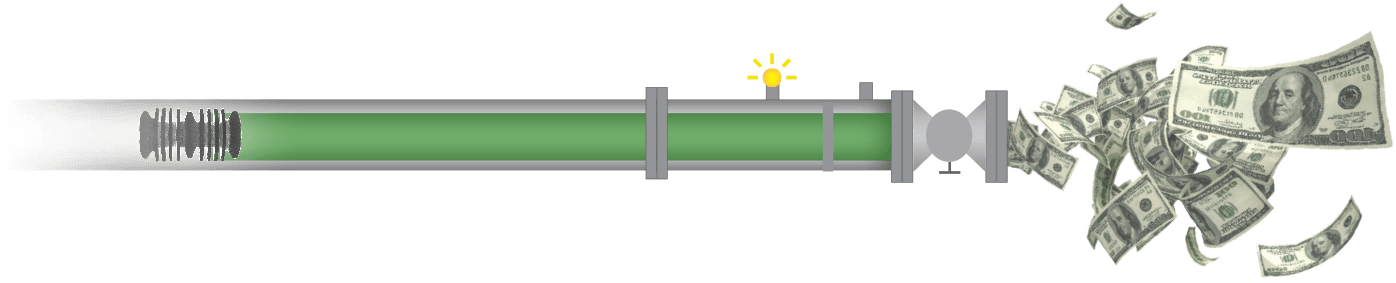

Hygienic pigging systems commonly have rapid payback periods and high returns on investment. Paybacks are, on average, less than 12 months and frequently less than 6 months. These savings are most often a result of following of pigging system benefits:

- Recovery of previously trapped and lost product

- Reduced flush waste, disposal expense, and on-site waste recovery or treatment cost

- Reduced off-spec product and rework expense

- Higher and more predictable product quality

- Reduced raw material and energy consumption

- Rapid and more frequent product change-overs without increased flush or cross-contamination risk

- Lower finished product inventory requirements

- Increased flexibility for product line growth and reduced need for dedicated product piping and installation cost

- Separation of plant functions by long distances. Transfer line routings can be used that maximize plant efficiency, space utilization, and safety needs.

- Achievement of sustainable manufacturing, continuous improvement, best practices, and environmental stewardship goals